Unlock greater value from your gold operations

From comminution to refining, Mipac helps gold producers like Barrick Mining stabilise processes, improve recovery, and modernise control systems.

Mipac partners with Operations Managers and Metallurgists at gold producers to cut variability, optimise circuits, and achieve stronger returns across the value chain.

Mipac delivers for Gold Producers

For more than 28 years, Mipac has delivered control, automation, and process optimisation solutions across gold operations worldwide. Our engineers have worked on some of the most complex comminution, flotation, leaching, and smelting challenges, helping producers like Evolution and Ok Tedi run safer, more efficient plants.

Our work with a leading gold producer demonstrates how targeted control improvements can unlock millions in added value and measurable gains in performance

Process Control Improvements for an Australian gold producer

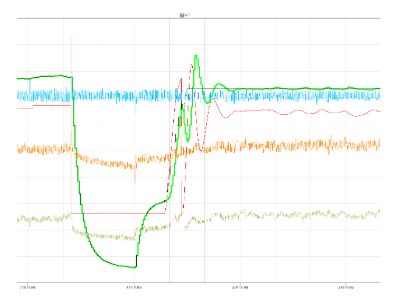

Mipac’s site audit and optimisation program delivered measurable gains for a gold and silver operation.

- A 9% lift in throughput

- Higher recoveries (4% gold and 19% silver)

- Full utilisation of automated controls

Together these improvements added an estimated 20% to EBITDA, valued at ~$32M USD annually.

Loop tuning: the ideal starting point

If your goal is to reduce plant variability and increase production, loop tuning is the fastest way to start. Our loop tuning experts identify control loops causing instability, apply proven tuning techniques, and deliver measurable gains in throughput and recovery with minimal disruption.

Get in touch to learn more

We’ve supported gold producers like Barrick Mining across the globe with practical, measurable improvements.

Here are just a few examples:

Ok Tedi Kiunga

Operations Control and Instrument Upgrade

Mipac upgrade this gold facility with ABB 800xA DCS, enhanced instrumentation, operator training and remote commissioning to boost uptime and data visibility

Evolution Cowal

Underground Control System Integration

Mipac integrated underground control systems at this gold mine using Yokogawa Centum VP, enabling centralised monitoring, faster safety alerts, and improved operational oversight.

Newcrest Gosowong

Process Control Improvements

Mipac assessed a gold plant’s mixed control systems, delivering 160+ improvements in instrumentation, safety, strategy and operations to enhance stability and performance

How experience in gold processing can support Barrick Mining's operations

Mipac’s gold sector expertise spans every stage of processing. We deliver practical projects that reduce risk, stabilise operations, and lift recovery.

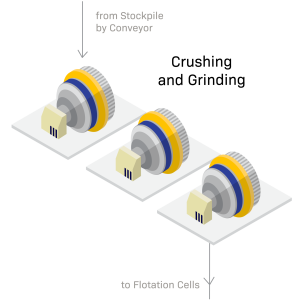

Comminution

- Upgrade and integrate control systems for crushing and grinding plants to improve throughput.

- Implement advanced control strategies to stabilise SAG and ball mill circuits, reducing unplanned downtime.

- Deploy real-time monitoring dashboards to track mill load, energy use, and ore variability.

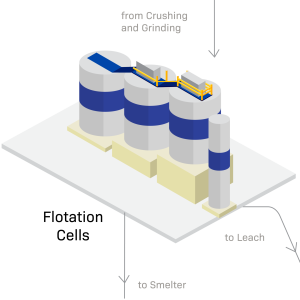

Flotation

- Optimise flotation cells with improved level control, reagent dosing, and air flow management.

- Introduce circuit-wide performance monitoring to identify bottlenecks and improve recovery rates.

- Commission digital twin simulations for flotation plants to test and tune strategies without disrupting production.

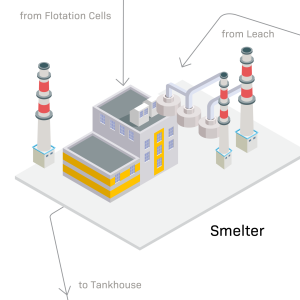

Smelting & Refining

- Implement furnace control systems to improve stability, reduce energy use, and extend refractory life.

- Upgrade SCADA and historian systems for improved data capture, reporting, and decision-making.

- Optimise gas handling and off-gas monitoring to improve safety and environmental compliance.

Ready to uncover new opportunities in your Barrick Mining operation?

FAQs that your team at Barrick Mining might be asking

Yes. Mipac specialises in layering on modern control strategies to legacy systems. We’ve upgraded control loops, introduced multi-output controllers, and improved network reliability while keeping core equipment in place. At complex operations like Nevada Gold Mines or Loulo-Gounkoto, these upgrades reduce downtime and lower maintenance risk, without the schedule or capex of a full rebuild.

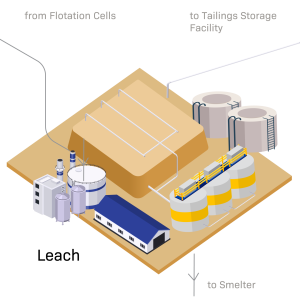

We first audit your control and feed strategies to identify variability (in ore feed, reagent dosing, pH, etc.). Then we apply process control improvements (better level control, replacing inefficient fuzzy logic systems, more precise feed regulation) to stabilise flotation and leaching circuits. These changes tend to deliver recovery gains of several percent, as we’ve done with other gold plants.

Mipac’s approach includes optimising reagent dosing, improving set-points, and automating dosing based on real-time process feedback (level control, sensor data). With more precise control, not only is reagent consumption reduced, but the downstream effect is less strain on equipment and less environmental risk.

Through process monitoring, control stability, loop tuning, better protective control logic, and predictive diagnostics, we reduce mechanical stress on crushers, mills, flotation and leaching equipment. When systems are stable and control loops work properly, mechanical failures drop, and scheduled maintenance becomes the norm instead of emergency.

We build dashboards, historian/SCADA upgrades, real-time KPIs tailored for gold operations (throughput, P80, recovery, energy intensity, chemical use). We also provide anomaly detection so you see drift before it hits recovery or cost thresholds. For example, at operations such as Pueblo Viejo or Nevada Gold Mines, these insights enable faster corrective actions and lower overall operational risk.

On top of that, Mipac’s MPA suite of software applications takes reporting and visibility further. Tools like TCard for task management, MPA Monitor for real-time process tracking, and advanced analytics applications enable structured visibility across the plant. This means less time wrestling with spreadsheets, more time acting on insights, and a smoother flow of information from operators on the ground to managers making strategic decisions.